Process Fluid Dynamics and Turbomachinery

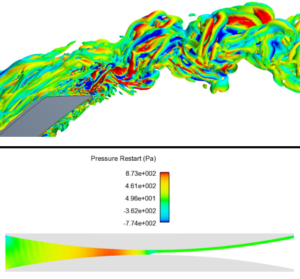

Bottom: Film splitting in the coating gap at a reverse roll coating process (numerical simulation, VOF-method)

The research group „Process Fluid Dynamics and Turbomachinery“ deals with fluid mechanical and thermodynamical processes in the fields of process-, food- and medical engineering as well as development, design and optimization of turbomachines. Aside from the academical research the group successfully collaborates with industry.

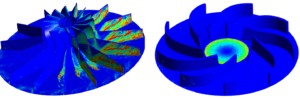

In the field of turbomachinery the research group has long-term experience in designing and optimizing blowers for household appliances. Additionally, fans and blowers for special purposes are a main area of research, for example fans for respiratory devices, tunnel ventilation or large-scale blowers for pyrolysis plants. The group also has great expertise in the field of centrifugal pumps, especially pumps for wastewater applications.

The research field of process fluid dynamics is mainly filled with topics from life sciences. Core topics here are personalozied respiration and coating of transdermal therapeutical systems as well as novel cooling and drying technologies for food processing technology.

Based on the application the research group works with analytical, numerical or experimental methods.

No projects found.

Erosion optimzed blowers

Modeling erosion in turbomachinery is still a challenge to many academics and constructers. Although many models may exist, it is still mainly empirical and experimental. Through this work, it is to numerically study erosion in turbomachinery and to develop new turbomachinery design methods capable of producing low erosion fans and pumps and to develop existing erosion models to better describe its effects. The benefit of these methods regarding erosion are studied through CFD simulation coupled with erosion modeling as well as through experiment.

Software

- ANSYS CFX, ANSYS Fluent, ANSYS Polyflow

- Siemens Star-CCM+

- Flow-3D

- OpenFOAM

- Siemens NX

- MATLAB

- LabVIEW

Test benches

- Test rig for centrifugal pumps

- Suction side test chamber for small fans and blowers

- 5 generations artifical lung test bench

2019

- , :

Numerical investigation of trailing edge flow in centrifugal pump impellers

13th European Turbomachinery Conference on Turbomachinery Fluid Dynamics and Thermodynamics, ETC 2019 (Lausanne, 8. April 2019 - 12. April 2019)

In: 13th European Turbomachinery Conference on Turbomachinery Fluid Dynamics and Thermodynamics, ETC 2019 2019 - , :

On the effect of trailing edge under-filing on the apparent slip factor of centrifugal impellers

ASME-JSME-KSME 2019 8th Joint Fluids Engineering Conference, AJKFluids 2019 (San Francisco, CA, 28. July 2019 - 1. August 2019)

In: ASME-JSME-KSME 2019 8th Joint Fluids Engineering Conference, AJKFluids 2019 2019

DOI: 10.1115/AJKFluids2019-5610 - , , :

Einflussfaktoren bei der Abkühlung von Backwaren

27. GALA-Fachtagung "Experimentelle Strömungsmechanik" (Erlangen, 3. September 2019 - 5. September 2019)

In: A. Delgado, B. Gatternig, M. Münsch, B. Ruck, A. Leder (ed.): Proceedings der 27. GALA-Fachtagung "Experimentelle Strömungsmechanik" 2019

2018

- , , :

A semi‐analytical approach for prediction of volume flow rate in nip‐fed reverse roll coating process

In: Proceedings in Applied Mathematics and Mechanics 18 (2018)

ISSN: 1617-7061

DOI: 10.1002/pamm.201800317

2017

- , , , :

Numerical and experimental investigation of trailing edge modifications of centrifugal wastewater pump impellers

ASME 2017 Fluids Engineering Division Summer Meeting, FEDSM 2017 (Waikoloa/Hawaii, 30. July 2017 - 3. August 2017)

In: ASME 2017 Fluids Engineering Division Summer Meeting 2017

DOI: 10.1115/FEDSM2017-69123

2014

- , :

On the effect of volute design on unsteady flow and impeller-volute interaction in a centrifugal pump

In: American Society of Mechanical Engineers, Fluids Engineering Division (Publication) FEDSM, -: -, 2014, p. 1-12

ISBN: 978-0-7918-4622-3

DOI: 10.1115/FEDSM2014-21533

URL: http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=2086849

2012

- , , , , :

Prediction of the flow characteristics of an axial fan at off design

Conference on Modelling Fluid Flow (CMFF 12) (Budapest, Ungarn)

In: Proceedings of the Conference on Modelling Fluid Flow 2012 - , , , , , , :

System matched 3D radial impeller design with variable inlet angle distributions

Turbine Technical Conference & Exposition (ASME Turbo Expo) (Kopenhagen, Dänemark, 11. June 2012 - 15. June 2012)

In: Proceedings of ASME Turbo Expo 2012 2012

DOI: 10.1115/GT2012-70024

URL: http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=1694340

2011

- , , , , :

Radial impeller design optimization matched for high efficiency fans

ASME 2011 International Mechanical Engineering Congress and Exposition, IMECE 2011 (Denver, USA, 11. November 2011 - 17. November 2011)

In: ASME 2011 International Mechanical Engineering Congress and Exposition (IMECE 2011) 2011

DOI: 10.1115/IMECE2011-65450

URL: http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=1644090 - , , , , , , , :

CFD computation, analysis and design of a two-bladed wastewater pump

ASME 2011 International Mechanical Engineering Congress and Exposition (IMECE 2011) (Denver, USA, 11. November 2011 - 17. November 2011)

In: ASME 2011 International Mechanical Engineering Congress and Exposition (IMECE 2011) 2011

DOI: 10.1115/IMECE2011-64195

URL: http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=1644076