Flows with Chemical Reactions

Research group B2 Flows with Chemical Reactions – Combustion Technology was established as a part of LSTM in 1996. Research conducted by the B2 group is strongly application oriented and includes experimental research of flows with chemical reactions, as well as heat and mass transfer processes, all supported through virtual engineering and numerical simulations (CFD).

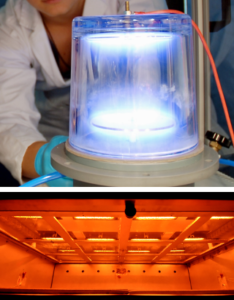

The most technically important representative of flows with chemical reactions are combustion processes, which represent the main research area of the B2 group. Different technologies have been developed here, from initial research to their technical implementation. The so-called volumetric ceramic burner technology (also known as porous burner technology) was developed at LSTM, it has been continuously optimized and adapted to a wide variety of applications, including steel, glass and food industry. Other important research point is investigation of non-thermal plasma, e.g. for water remediation and surface cleaning.

-

Entwicklung eines neuartigen Grundwassersanierungsverfahrens zur Beseitigung niedrig konzentrierter perfluorierter Tenside und ihrer Präkursoren mittels Behandlung durch Adsorption und nichtthermischem Plasma Delgado

(Third Party Funds Single)

Term: 1. February 2020 - 31. January 2022

Funding source: Bundesministerium für Wirtschaft und Technologie (BMWi)Das Projekt zielt auf eine neuartige Wassersanierungsmethode zur Beseitigung perfluorierter Tenside (PFT) aus Grund- und Abwasser mit einem deutlich höheren Wirkungsgrad als bisher erreichbar. PFT sind Organofluorverbindungen, die aufgrund ihrer Bioakkumulation und schlechten Abbaubarkeit in der Umwelt sowie wegen ihrer negativen Auswirkungen auf die menschliche Gesundheit bedenklich sind. In der Öffentlichkeit wurde man zunehmend auf PFT aufmerksam, daher bietet eine geeignete Wassersanierungsmethode einzigartige Marktchancen.

Die Möglichkeiten zur Beseitigung von PFT aus kontaminierten Gewässern sind aufgrund ihrer extremen chemischen Stabilität begrenzt. Die Hauptbehandlungsmethode ist die Adsorption mittels Aktivkohle, was aber mit hohen Betriebskosten verbunden ist. Die vorgeschlagene Methode besteht aus einer nicht-thermischen atmosphärischen Plasmabehandlung, bei der der Hauptanteil an PFT zersetzt wird, sowie der Adsorption durch Ionenaustauscher, bei der der Restanteil an PFT adsorbiert wird. Hierbei dienen numerische und experimentelle Untersuchungen sowie Dauertests an einem Testfeld zur Verifikation und Charakterisierung des neuartigen Wassersanierungskonzepts.

-

LOHCmobil - H2 Verbrenner/ Konstruktion und Erprobung des volumetrischen keramischen Brenners

(Third Party Funds Single)

Term: 1. January 2018 - 31. December 2020

Funding source: Bundesministerium für Wirtschaft und Technologie (BMWi)Das Ziel des Projekts ist die Entwicklung eines deutlich kompakteren und dynamischeren Wasserstoff-Freisetzungsverfahrens auf Basis eines volumetrisch-keramischen Brenners mit entsprechendem Kesselsystem zum Einsatz in stationären und mobilen Wasserstofffreisetzungsanlagen und dessen allgemeingültige effiziente Integration und Anpassung in diese Anlagen, um die Kommerzialisierung der Wasserstoffspeicherung in LOHC im Markt voran zu treiben. Das neue Verfahren soll den Eigenverbrauch an Wasserstoff für die Verbrennung bei einer 100 kW Wasserstofffreisetzungsanlage von derzeit etwa 45 kW auf insgesamt angestrebte 30 kW reduzieren. Zudem soll das neue Verfahren deutlich kompakter und dynamischer sein als derzeit auf dem Markt vorhandene Brennersysteme. Die ermöglichten, schnellen Lastwechsel sollen die Integration in mobile Anwendungen ermöglichen.

-

Systematische Untersuchungen zur Einsatzqualifizierung einer innovativen Backofentechnik mit volumetrischem keramischem Brenner (VKB) einstellbaren Wellenlängenspektrums sowie hoher Regeldynamik und Energieeffizienz

(Third Party Funds Single)

Term: 1. May 2014 - 30. April 2017

Funding source: AIF Arbeitsgemeinschaft industrieller ForschungsvereinigungenAs part of thisresearch project, a possibility of application of a novel gas-fired baking oventechnology is to be developed, in which for the first time in the food industrya volumetric ceramic burner (VCB) is to be used. In many other industrialfields, VCB systems have demonstrated superior energy utilization and processecology. A VCB-based baking oven technology combines the benefits of energytransfer, primarily due to thermal radiation, with a broad power modulationrange. Thus, it promises not only the possibility of influencing the wavelengthspectrum and its radiation intensity, but also an otherwise unattainablecontrol dynamics, which is needed for the design and implementation of variousbaking programs, and the resulting increased energy efficiency. A VCB-based gas-firedbaking oven technology therefore offers particular advantages to small andmedium-sized enterprises (SMEs), which frequently vary their product range and productioncapacities.

The baking oven type, the design of the thermal energy supply system, themoisture content in the baking oven and the baking time have a decisive effecton the resulting mass and energy transport conditions. However, there is a lackof knowledge about required optimal process conditions. Experimental studieshave shown the positive influence of thermal radiation on the baking process, e.g.reduction of energy required for the baking process and improvement of transferredthermal energy control and regulation. In this regard, there are so farinsufficient data regarding the optimal wavelength range for baking purposes.

The aim of this research project is development and operational qualificationfor a novel gas-fired baking oven concept based on a volumetric ceramic burner.Potential for application of this technology requires a critical evaluation ofthe operating window in interaction with product properties and processparameters. An additional goal is to explore which process conditions can berealized in the novel gas-fired furnace through the specific use of theinnovation-bearing characteristics, its control and wide dynamic powermodulation range and increased energy efficiency. The interdisciplinary projectis intended to create the basis for a fast and broad transfer of an innovativebaking technology and is thus of relevance to both companies in the field of bakingoven construction and users in the baking industry. In particular, SMEs willbenefit from the results, as their competitiveness can be increased by costsavings of 20 to 30% of energy costs for baking processes.

Topics, currently or previously addressed in projects, include:

- burners and combustion systems,

- porous volumetric ceramic burner technology,

- combustion of hydrogen and of low calorific gases,

- heating systems,

- industrial combustion units,

- biomass gasification,

- drying facilities,

- steam generators,

- thermal energy recovery from exhaust gases,

- flue gas treatment,

- fuel cells,

- hot jets,

- non-thermal (cold) plasma applications,

- wastewater treatment,

- investigation of high-temperature resistant ceramics,

- numerical simulations of flows and of combustion processes,

- development of sensors and measurement systems, etc.

Experimental facilities:

- Five laboratories for the experimental research, including three bunker laboratories,

- Three gas analyzers (for O2, CH4, CO2, CO, NO, NOx, etc.)

- FID – analyzer (C3 equivalent)

- Thermography system (50 Hz)

- IR Color (Dual frequency) Pyrometer

- 16 long-term test setups for burners (24/7 use)

- High temperature furnace TMAX = 1750°C

- Vacuum and atmospheric plasma generator

Numerical simulations are used in addition to the experimental investigation, by means of various commercial and open source simulation codes.

2023

- , , , , , :

Influence of Non-Thermal Plasma Treatment on Structural Network Attributes of Wheat Flour and Respective Dough

In: Foods 12 (2023), Article No.: 2056

ISSN: 2304-8158

DOI: 10.3390/foods12102056 - , , , , , , , :

Numerical and experimental investigation of irradiance profiles on suspended particles in a flat disk photoreactor for hydrogen generation

In: Chemical Engineering Science 282 (2023), Article No.: 119298

ISSN: 0009-2509

DOI: 10.1016/j.ces.2023.119298 - , , , :

Thermal stability of film forming amines-based corrosion inhibitors in high temperature power plant water solutions

In: Energy Science and Engineering (2023)

ISSN: 2050-0505

DOI: 10.1002/ese3.1625

2022

- , , :

Simulation of a Hydrogen-Air Diffusion Flame under Consideration of Component-Specific Diffusivities

In: Applied Sciences 12 (2022), Article No.: 3138

ISSN: 2076-3417

DOI: 10.3390/app12063138 - , , , :

Hollow spheres as inert packed bed from lean to rich combustion in porous media

In: International Journal of Heat and Mass Transfer 195 (2022), Article No.: 123067

ISSN: 0017-9310

DOI: 10.1016/j.ijheatmasstransfer.2022.123067 - , , , :

Enhancement of Wheat Flour and Dough Properties by Non-Thermal Plasma Treatment of Wheat Flour

In: Applied Sciences 12 (2022), Article No.: 7997

ISSN: 2076-3417

DOI: 10.3390/app12167997 - , , , , , :

Effectiveness of Non-Thermal Plasma Induced Degradation of Per- and Polyfluoroalkyl Substances from Water

In: Water 14 (2022)

ISSN: 2073-4441

DOI: 10.3390/w14091408

2021

- , , , , , , :

Effect of Steam Flow Rate and Storage Period of Superhydrophobic-Coated Surfaces on Condensation Heat Flux and Wettability

In: Multimodal Technologies and Interaction 9 (2021), Article No.: 1958

ISSN: 2414-4088

DOI: 10.3390/pr9111958

2020

- , , , , , :

Static wettability of differently mechanically treated and amphiphobic-coated aluminium surfaces

In: Materials 13 (2020), Article No.: 2240

ISSN: 1996-1944

DOI: 10.3390/ma13102240 - , , , :

Role of Individual Heat Transfer Mechanisms Within a Model Baking Oven Heated by Porous Volumetric Ceramic Burners

In: Frontiers in Chemistry 8 (2020), Article No.: 511012

ISSN: 2296-2646

DOI: 10.3389/fchem.2020.511012 - , , , , , :

Evaluation of baking performance by means of mid-infrared imaging

In: Innovative Food Science & Emerging Technologies 61 (2020), Article No.: 102327

ISSN: 1466-8564

DOI: 10.1016/j.ifset.2020.102327

2019

- , , , , , :

Investigation of the Concepts to Increase the Dew Point Temperature for Thermal Energy Recovery from Flue Gas, Using Aspen®

In: Energies 12 (2019), Article No.: 1585

ISSN: 1996-1073

DOI: 10.3390/en12091585 - , , , , :

Experimental investigation of the gravity influence on the condensation behaviour on Al and PTFE-samples

27. GALA-Fachtagung "Experimentelle Strömungsmechanik" (Erlangen, 3. September 2019 - 5. September 2019)

In: A. Delgado, B. Gatternig, M. Münsch, B. Ruck, A. Leder (ed.): Proceedings der 27. GALA-Fachtagung "Experimentelle Strömungsmechanik" 2019 - , , , :

Numerical study of the methane-air combustion in the direct-flow burner of the boiler 300 MW TGMP-314 boiler

2nd International Conference on Fusion Energy and Plasma Technologies, ICFEPT 2019 (Moscow, 7. October 2019 - 9. October 2019)

In: Journal of Physics: Conference Series 2019

DOI: 10.1088/1742-6596/1370/1/012006 - , :

Neuartiges Ofenkonzept

In: brot+backwaren (2019), p. 40-45

ISSN: 0172-8180 - , :

Novel baking concept based on the Volumetric Ceramic Burners VCB

World Congress on Advances in Nano, Bio, Robotics, and Energy ANBRE19 (Jeju Island, 17. September 2019 - 21. September 2019)

In: Proceedings of 2019 World Congress on Advances in Nano, Bio, Robotics, and Energy ANBRE19 2019 - , , :

New oven concept with dominant near-infrared (NIR) thermal radiation heat transfer

In: Cereal Technology [Getreidetechnologie] (2019), p. 40-51

ISSN: 1869-2303

DOI: 10.23789/1869-2303-2019-1 - , , , , , , :

Impact of non-thermal plasma on the abatement of Perfluorinated compounds present in minute quantities in water effluents

27. GALA-Fachtagung "Experimentelle Strömungsmechanik" (Erlangen, 3. September 2019 - 5. September 2019)

In: A. Delgado, B. Gatternig, M. Münsch, B. Ruck, A. Leder (ed.): Proceedings der 27. GALA-Fachtagung "Experimentelle Strömungsmechanik" 2019 - , , , , , , :

Experimental and numerical analysis of the heat transfer in a packed bed exposed to the high thermal radiation flux

In: International Journal of Heat and Mass Transfer 136 (2019), p. 383-392

ISSN: 0017-9310

DOI: 10.1016/j.ijheatmasstransfer.2019.03.009

URL: https://www.sciencedirect.com/science/article/pii/S0017931018357922?via=ihub#!

2018

- , :

VCB based baking oven concept - efficient, innovative and flexible

In: The Future of Baking: Science-Technique-Technology, Hamburg: f2m foodmultimedia GmbH, 2018, p. 10-17

ISBN: 978-3-9817514-4-4 - , , , , , , :

Degradation of Low Concentrated Perfluorinated Compounds (PFCs) from Water Samples Using Non-Thermal Atmospheric Plasma (NTAP)

In: Energies 11 (2018)

ISSN: 1996-1073

DOI: 10.3390/en11051290

URL: https://www.mdpi.com/1996-1073/11/5/1290/htm - , , , :

Virtual engineering as a base for the novel deck baking oven design

32nd International Conference of European Federation of Food Science and Technology (Nantes, 6. November 2018 - 8. November 2018) - , , , , , , :

Syngas production from waste tires using a hybrid filtration reactor under different gasifier agents

In: Energy Conversion and Management 172 (2018), p. 281-390

ISSN: 0196-8904

DOI: 10.1016/j.enconman.2018.07.046

2017

- , , , , , :

Energieeffizientes Backen mittels innovativer VKB-Technologie: Vom Hartgebäck bis zum Weißbrot

FEI-Jahrestagung 2017 - Industrielle Gemeinschaftsforschung als Katalysator des innovativen Mittelstands (Bonn, 4. September 2017 - 6. September 2017)

DOI: 10.13140/RG.2.2.27374.10561

URL: http://www.fei-bonn.de/veranstaltungen-termine/jahrestagungen/jahrestagung-2017 - , , , , , :

Combustion of solid fuel in a hybrid porous reactor

In: Energy Procedia 120 (2017), p. 431-438

ISSN: 1876-6102

DOI: 10.1016/j.egypro.2017.07.202 - , , , , :

Experimental Investigation of Solid Fuel Combustion Process in a Hybrid Porous Reactor

In: Journal of Energy and Power Engineering 11 (2017), p. 589-596

ISSN: 1934-8975

DOI: 10.17265/1934-8975/2017.09.004

URL: https://www.davidpublisher.com/Public/uploads/Contribute/59cc53e9610bc.pdf - , , , , :

Cleaning of the surfaces in the food industry using cold plasma

25. GALA-Fachtagung "Experimentelle Strömungsmechanik" (Karlsruhe, 5. September 2018 - 7. September 2018)

In: Ruck, Bodo; Gromke, Christop ; Leder, Alfred; Dopheide, Dietrich (ed.): Proceedings der 25. GALA-Fachtagung "Experimentelle Strömungsmechanik", Karlsruhe: 2017 - , , , , :

Application of the porous Volumetric Ceramic Burner for Bread Baking in a Deck Baking Station

XXIII internationales Symposium "Research-Education-Technology" (Stralsund, 12. October 2016 - 13. February 2019)

In: Proceedings of 23rd International Symposium, Research-Education-Technology (RET) 2017 - , , , , :

Development and evaluation of the novel baking concept based on a highly radiative volumetric ceramic burner (VCB)

FEI Jahrestagung 2017 - Industrielle Gemeinschaftsforschung als Katalysator des innovativen Mittelstands (Bonn, 4. September 2017 - 6. September 2019)

DOI: 10.13140/RG.2.2.15630.05448 - , , , , , :

Mehr Effizienz - Volumetrische keramische Brenner - eine innovative, energieeffiziente Technologie für den Backprozess

In: Backtechnik Europe 4 (2017), p. 42-45

ISSN: 2192-824X

2016

- , , , , :

Hydrocarbons conversion to syngas in inert porous media combustion

In: International Journal of Hydrogen Energy Vol. I (2016), p. 5867-5864

ISSN: 0360-3199

DOI: 10.1016/j.ijhydene.2016.02.065

URL: http://www.sciencedirect.com/science/article/pii/S036031991531541X?via=ihub

2015

- , , , , :

Influence of the Inter-structural Gap between the Combustion Zone and the Flame Trap on the Properties of the dual Layer Porous Burners in Operation

7th European Combustion Meeting (Budapest)

In: Proceedings of the 7th European Combustion Meeting 2015 - , , , , :

Comparison of the operational characteristics of the commercially available and newly developed porous burner flame traps for high temperature applications

27. Deutscher Flammentag - Verbrennung und Feuerung (Clausthal-Zellerfeld)

In: Verbrennung und Feuerung : 27. Deutscher Flammentag, Düsseldorf: 2015 - , , , , , , :

Overview of experimental evaluation of innovative non-thermal plasma treatment of biotic and abiotic matter

International Nonthermal Processing Workshop (Athen)

In: Proceedings of the International Nonthermal Processing Workshop 2015 - , , , , , , , :

Investigation of advanced temperature and thermo shock resistant ceramic components for high temperature porous burners

European Conference on Industrial Furnaces and Boilers (INFUB) (Gaia (Portugal))

In: Proceedings of the 10th European conference on industrial furnace and boilers 2015

URL: https://www.researchgate.net/publication/280881956_Investigation_of_advanced_temperature_and_thermo_shock_resistant_ceramic_components_for_high_temperature_porous_burners - , , :

Numerical simulation of interfacial closures for 3D bubble column flows

In: Chemical Engineering & Technology 38 (2015), p. 777-786

ISSN: 0930-7516

DOI: 10.1002/ceat.201400182

URL: http://onlinelibrary.wiley.com/doi/10.1002/ceat.201400182/pdf - , , , :

Characterization of the heat transfer within the baking oven based on the volumetric ceramic burner (VCB) technology

29th EFFoST Conference - Food Science Research and Innovation: Delivering sustainable solutions to the global economy and society (Athen)

In: 29th EFFoST Conference Proceedings - Food Science Research and Innovation: Delivering sustainable solutions to the global economy and society 2015

2014

- , , , :

Spektroskopische Untersuchung und Charakterisierung der Nah-Infrarot (NIR) Strahlung eines volumetrischen keramischen Porenbrenners

Lasermethoden in der Strömungsmesstechnik (Karlsruhe)

In: Proceedings der 22. GALA-Fachtagung "Lasermethoden in der Strömungsmesstechnik" 2014 - , , :

Bildung, Verhalten und Lebensdauer von Plasmabullets in einem kalten Plasmastrahl bei Atmosphärendruck

Lasermethoden in der Strömungsmesstechnik (Karlsruhe)

In: Proceedings der 22. GALA-Fachtagung "Lasermethoden in der Strömungsmesstechnik" 2014 - , , , , , :

Numerical analysis of heat transfer characteristics in energy piles

In: Proceedings in Applied Mathematics and Mechanics 14 (2014), p. 757-758

ISSN: 1617-7061

DOI: 10.1002/pamm.201410361

URL: http://onlinelibrary.wiley.com/doi/10.1002/pamm.201410361/pdf

2013

- , , , :

Untersuchungen zur Vergasung von Biomasse mit nicht-thermischem Stickstoff Plasma

26. Deutscher Flammentag (Duisburg)

In: VDI-Berichte: 26. Deutscher Flammentag "Verbrennung und Feuerung", Düsseldorf: 2013 - , , , :

Experimentelle Untersuchungen zur Vergasung von Biomasse mit nicht-thermischem Stickstoff Plasma

Lasermethoden in der Strömungsmesstechnik (München, 3. September 2013 - 5. September 2013)

In: Deutsche Gesellschaft für Laser-Anemometrie GALA e.V. (ed.): Proceedings der 21. GALA-Fachtagung "Lasermethoden in der Strömungsmesstechnik" 2013 - , , , , , :

Optimization of inlet mixture quality by means of third gas for regenerative porous burners with highly preheated air

European Combustion Meeting (ECM 2013) (Lund, Schweden)

In: Proceedings of the 6th European Combustion Meeting (ECM 6) 2013

2011

- , , , :

Gasification of jordanian oil shale using a nitrogen non-thermal plasma

31st Oil Shale Symposium (Golden, Colorado (USA))

In: Proceedings of 31st Oil Shale Symposium 2011 - , , , , :

Development and testing of a new concept for regenerative porous burner with preheated air

9th European conference on industrial furnaces and boilers (Estoril, Portugal)

In: Proceedings of the 9th European conference on industrial furnaces and boilers, Estoril, Portugal: 2011 - , , , , :

Optimization of Fuel Inlet Configuration for Porous Burners with Preheated Air

European Combustion Meeting (Cardiff)

In: Proceedings of the European Combustion Meeting 2011 2011

2010

- , , , , :

Experimental Results of Long Time Tests of Porous Burners with Ceramic Housing for High Temperature Application in Glass Industry

High temperatures ceramic materials and composites : 7th International Conference on High Temperature Ceramic Matrix Composites (HT-CMC 7) (Bayreuth)

In: High temperatures ceramic materials and composites : Proceedings 7th International Conference on High Temperature Ceramic Matrix Composites (HT-CMC 7), Berlin: 2010