Equipment

Test Facilities

Wind Tunnel

- Test cross-section 1,87m x 1,40m,

- Maximum flow velocity 55 m/s

- Turbulence intensity < 0,4%

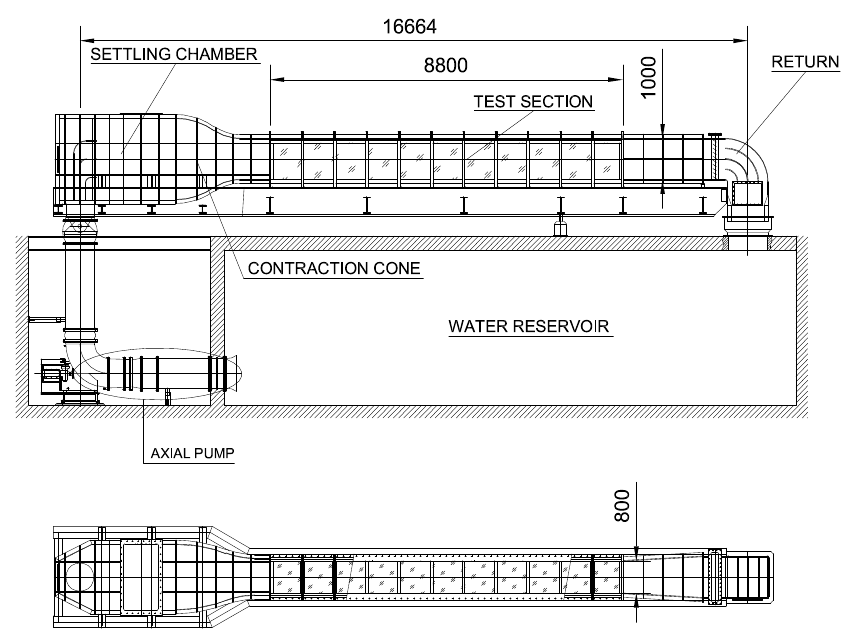

Water Tunnel

- Test cross-section 0,80m x 1,00m

- Length of the test-section 8,8 m

- Maximum flow velocity 2,5 m/s

- Turbulence intensity < 2%

- Contraction ratio 4:1

Oil Tunnel - Matched Index of Refraction (MIR)

- Test cross-section 0,60m x 0,45 m

- Maximum flow velocity 4,8 m/s

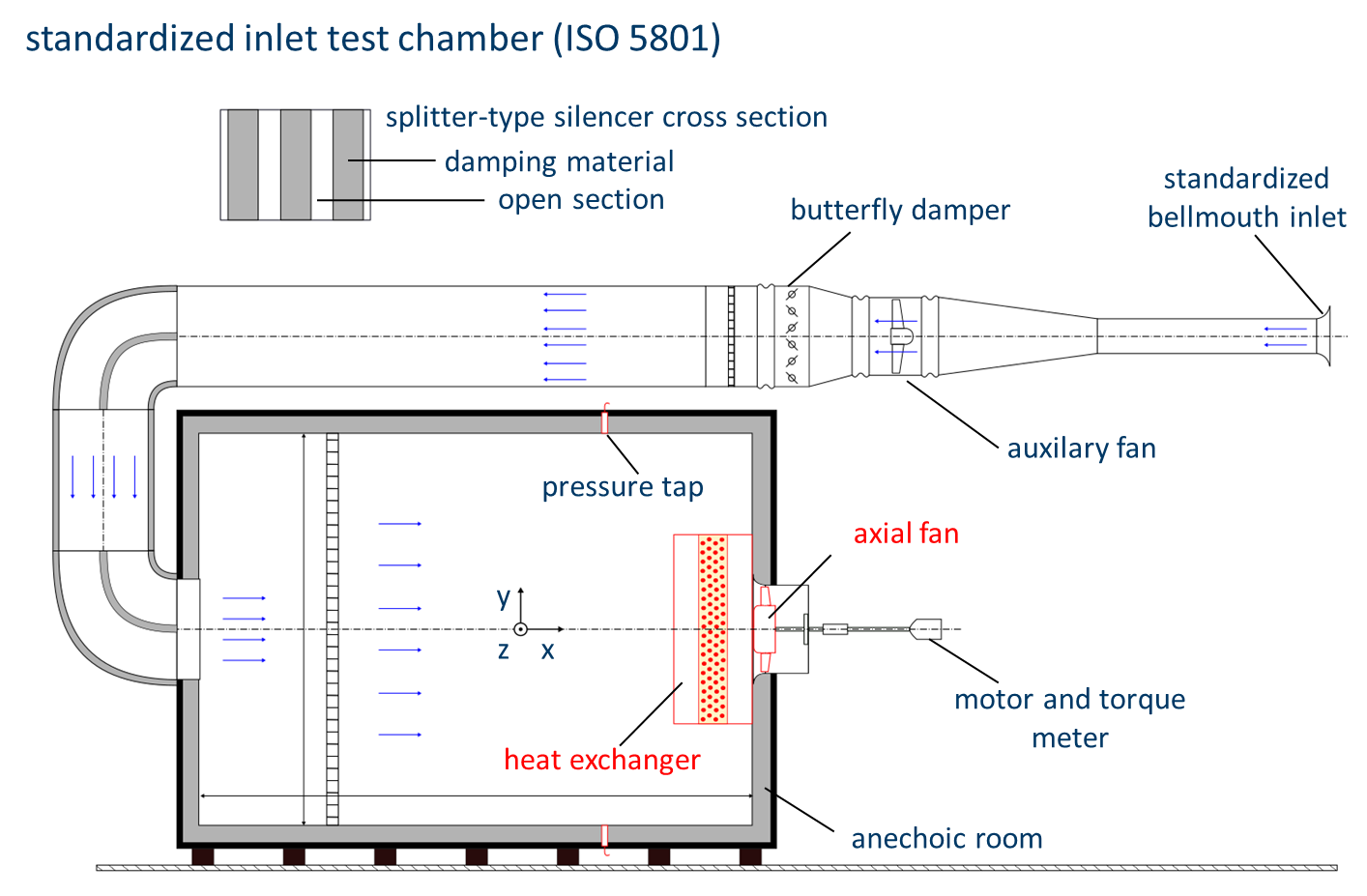

Aeroacoustic Wind Tunnel

-

- Test-Sections:

A1 = 0.2 m x 0.26 m

A2 = 0.25 m x 0.33 m

A3= 0.35 m x 0.5 m - Max. Velocity:

U1= 55 m/sec (200 km/h)

U2 = 35 m/sec (125 km/h)

U3 = 20 m/sec (72 km/h)

- Max. Volume Rate: 2.8 m³/s

- Turbulence Level: < 0.22 %

- Velocity Profile: Difference < 0.5 % of the Mean Value

- Sound Level Lp in 1 m Distance: 72 dB(A) at U=50 m/sec

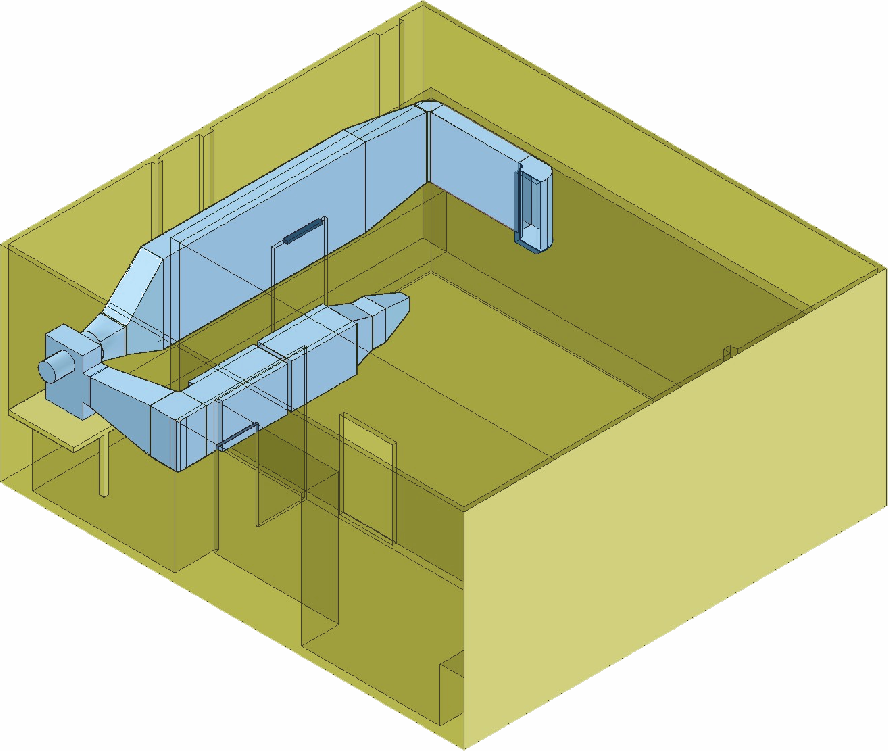

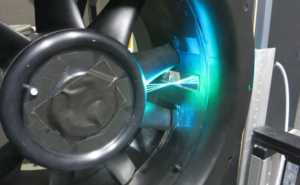

Axial Fan Test-Rig

- Measurements: Characteristic Line + Acoustics

- Dimension: 7m x 3.3 m 2.5m (LxHxB)

- Max. Volume rate: 3m³/s

- Max. Impeller diameter: D=1m

- Max. Pressure difference: 1300 Pa

![]()

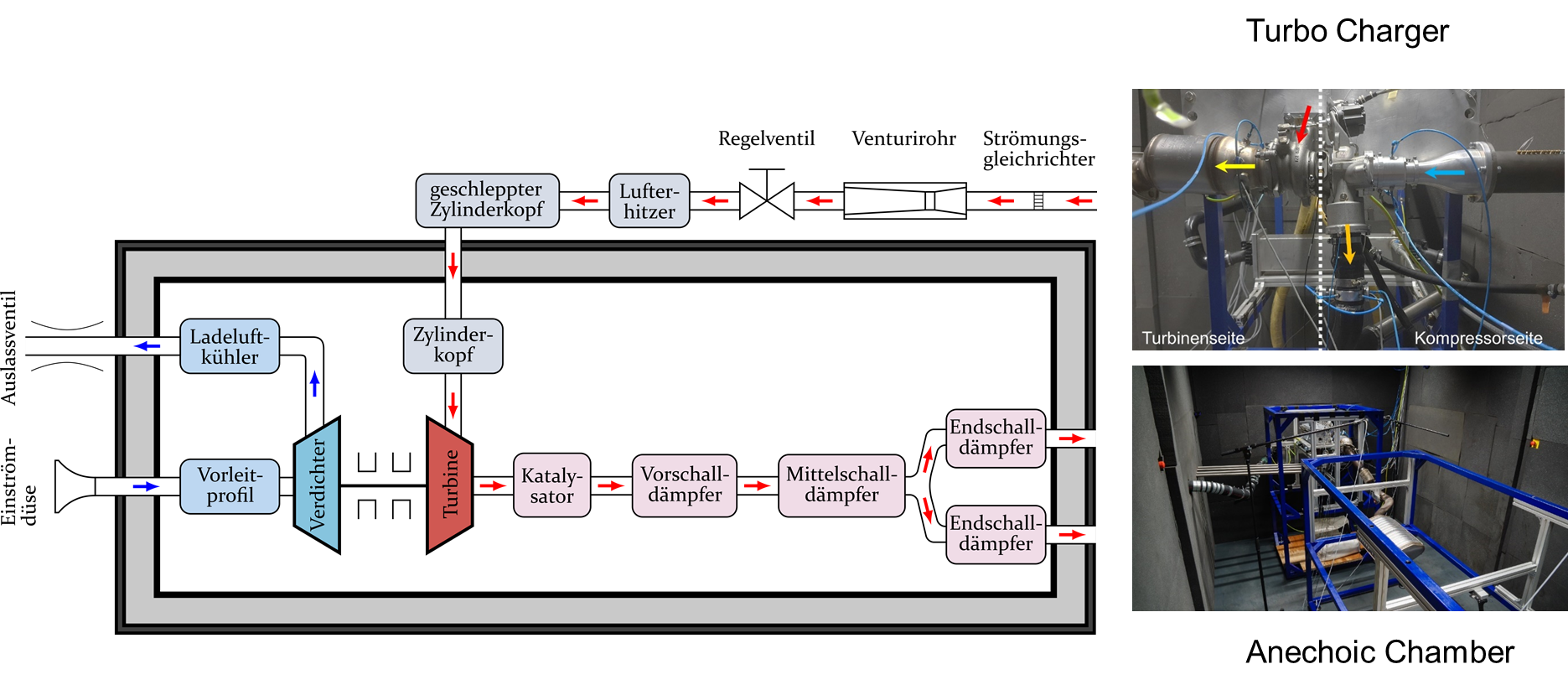

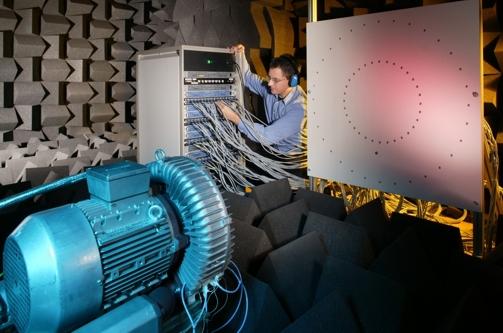

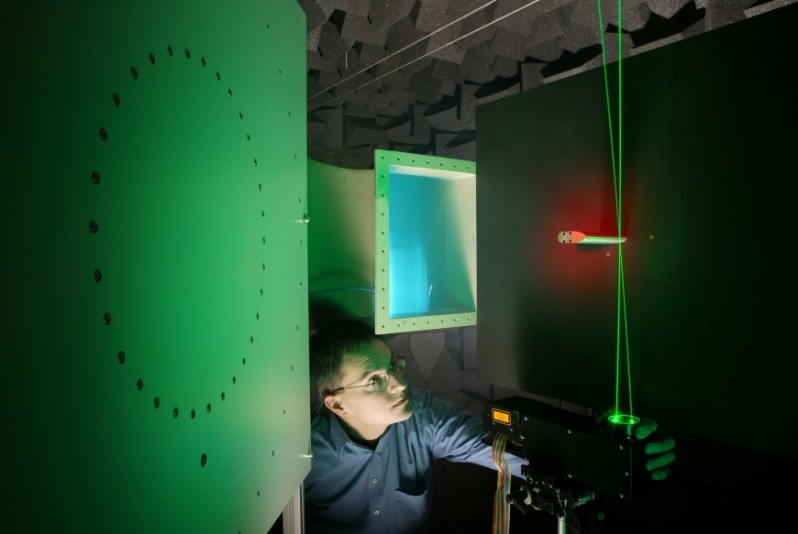

Anechoic Chamber

- Utilizes Flate Absorbers

- Volume: 5 m x 4.6 m x 3 m

- Cut-off Frequency 300 Hz

- Semi- and Full Free Field Conditions

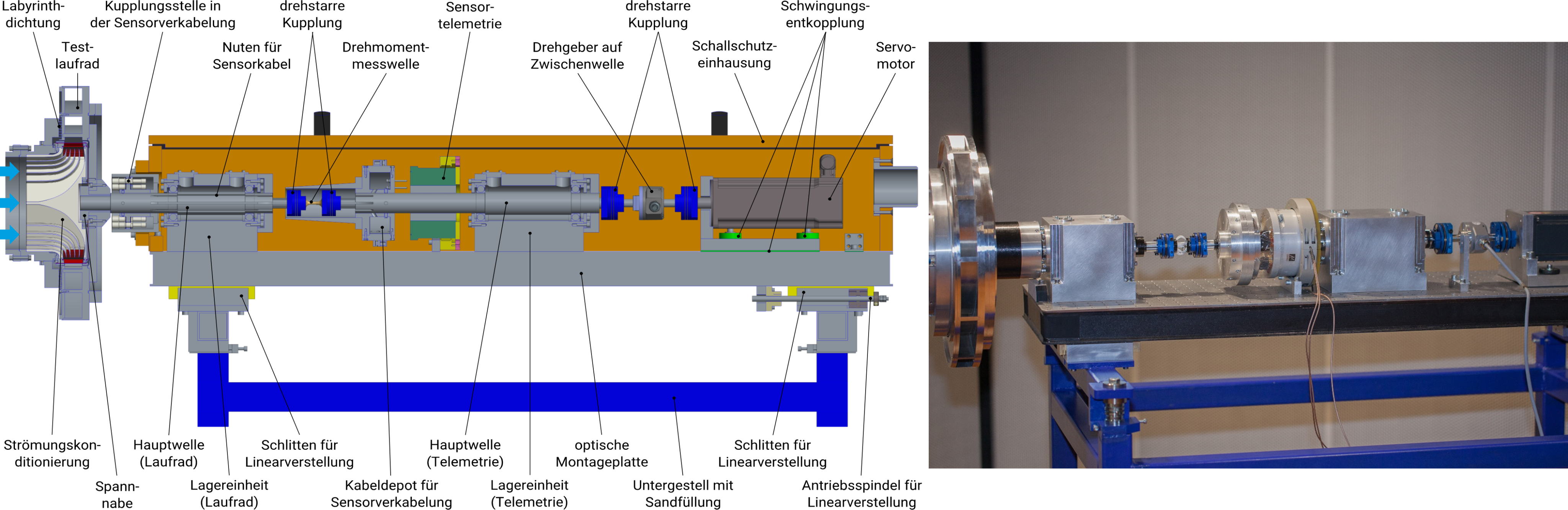

Radial Impeller Test-Rig

![]()

Test-Rig for Axial Fans in Pipes

Turbocharger – Cold Gas Test-Rig

- Pressure Supply: 8,5 bar

- Mass Flow Rate : ~ 800 kg/h

- max. TC– Rotation Speed : 140000 1/min

- Integration Slaved Motor

Two-Port Test-Rig

Rheology Laboratory

High-Pressure Laboratory

12 Test benches for 24h measurements (combustion technology)

Test-rig for centrifugal pumps

Suction side test chamber for small fans and blowers

5 Generations artificial lung test bench

Measurement Equipment

High-Speed Camera

Infrared Camera

High-pressure rheometer

Thin-film rheometer

Bubble column reactors

Exhaust analysis systems

High-temperature test bench

Test bench for CIP cleaning

Rheometric Measurement Equipment

- Narrow-gap rotational rheometer based on: Anton Paar MCR 501

- Narrow-gap rotational rheometer with optical access based on: Physica UDS 200:

- Parallel disks, diameter 12.5-50 mm

- Gap widths: oscillation down to 5 µm, rotation down to about 20 µm

- Shear rates: up to 150,000/s

- Temperature range: 20-40°C

- Features: Fluorescence microscope, birefringence, normal forces at high shear rates

- Ubbelohde viscometer: Schott, diverse

- High-pressure rolling ball viscometer: For pressures up to 700 MPa

- High-pressure falling ball viscometer: For pressures up to 700 MPa

- High-pressure torsional shear-wave rheometer: For pressures up to 300 MPaH

High-pressure devices

- Density: Jamin interferometer. Precise density measurements for transparent liquids and pressures up to 700 MPa

- Compressibility: Screw press. For liquids and pressures up to 700 MPa

- Thermal conductivity: Unsteady hot-wire method. For liquids and pressures up to 500 MPa

- Zero viscosity: Rolling ball viscometer: For liquids and pressures up to 700 MPa

- Zero viscosity: Falling ball viscometer: For transparent liquids and pressures up to 700 MPa

- Viscoelasticity: Torsional shear-wave rheometer. For pressures up to 300 MPa

- pH-value: Optical spectoscopy. Also for intransparent liquids and near solid surfaces. Pressures up to 700 MPa

- Melting curve, crystallization: Polarization microscope. For transparent samples and pressures up to 700 MPa

- Crystallization: Light scattering. For transparent samples and pressures up to 700 MPa

- Thermofluiddynamics: particle image velocimeter, Laser Doppler velocimeter, hot-wire anemometry, liquid crystal thermometry.For transparent samples and pressures up to 700 MPa

- Autoclaves with optical windows. Volumes ranging from 2 ml to 1.5 l. Automatically controlled. Pressures up to 700 MPa

- Autoclaves without optical access: 8 parallel autoclaves 32 ml volume each, 1 autoclave of 160 ml volume. Temperature, pressure, compression ramp, holding time, pressure cycles of each autoclave can be controlled independently. Pressures up to 900 MPa, temperature range from -20 °C to 80 °C

Acoustic Measurements

- Microphone- Array

- Multi Microphone Measurements (B&K)

- Microflown pu-Probe

- Sound Intensity Probe

- Artificial Heads (KEMAR, HEADAcoustics)

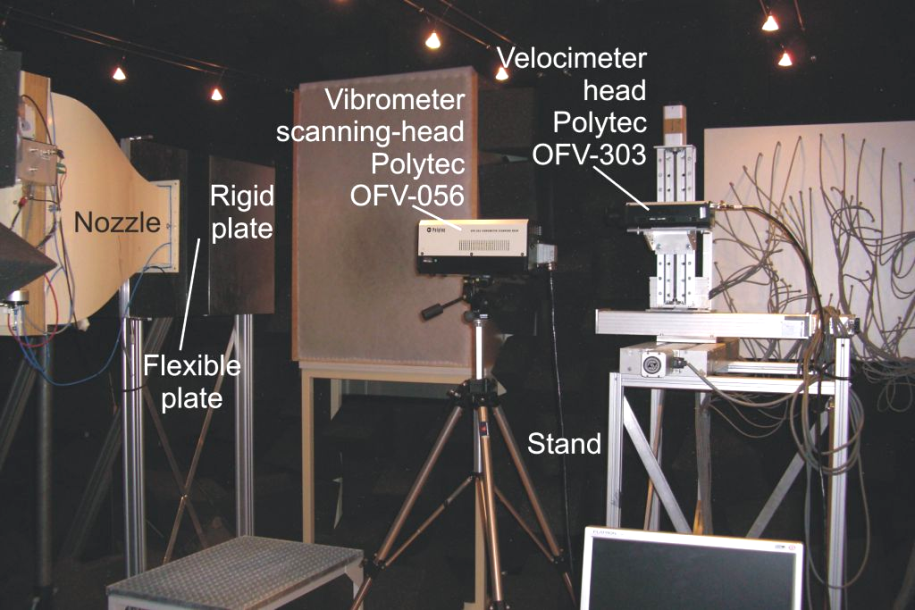

Vibration Measurements

-

- Laser Scanning Vibrometer

- Laser Vibrometer

- DMS

- Acceleration Sensors

- Force Measurements

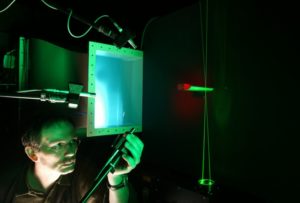

Flow Measurements

- Particle Image Velocimetry PIV

- High speed PIV

- Laser-Doppler-Anemometer LDA

- Phase-Doppler-Anemometer PDA

- 3D Hot Wire Measurements (Streamline)

- High Speed Flow Visualization

Pressure Measurements

- Multi Pressure System: 192 Channels (Pressure Systems)

- Multi Pressure System: instat. Pressure (Kulite): 64 Pressure Probes

- 16 – Channels Telemetric System

-

Data Analysis and Processing

- PXI Systeme (NI)

- LabView / MATLAB

- SQuadriga – ARTEMIS Software

-

Microphone Array – Rotating System

- Circular array with 64 microphones

- Setup on suction side

- Synchronous acquisition of microphone and rpm signal

- Virtual rotation of the array with the rotational speed of the fan

- Possibility of applying beam-forming algorithms in the frequency domain

-

Computer Hardware and Software

- CAD-Software

- CAE/CFD-Software

- Multiple commercial simulation software packages

- Nek5000: Fortran 77 spectral-element solver

- Neko (github): modern Fortran 2008 spectral-element solver

- Simson: Fortran 77 spectral solver for boundary layers (manual)

- OpenFOAM

- SU2

- FASTEST-3D (in-house CFD-Code under on-going development)

- Postprocessing software including VisIt, Paraview, Python, …

The High-Performance computing resources by the Regionales Rechenzentrum Erlangen (RRZE) enable us to perform large-scale simulations using massively parallel machines, including CPU and GPU clusters. We have also access to European machines via EuroHPC.

Workshops

- Mechanical Work Shop

- Electrical Work Shop